S&OP is a critical business process for transforming strategy into execution and driving supply chain performance. Even though technology has advanced, many companies are still stuck using old-fashioned and inefficient methods, And there are some big misconceptions that are getting in the way. They exist because businesses don’t fully understand what S&OP is really about. It is time to debunk the myths.

What is S&OP?

Let’s begin by discussing what S&OP – Sales and Operations Planning – actually entails. S&OP is a forward-looking planning process, superior to the operational process and subordinate to the strategic process, bridging the gap between the two. It serves as a mechanism for aligning a company’s strategic objectives with its operational activities.

S&OP is used to continuously identify disparities between a company’s desired goals and its current trajectory, and find strategies for closing these gaps. This can include a range of actions, such as intensifying sales efforts within specific markets or product segments, increasing manufacturing capacity to meet projected demands, or reallocating resources to areas where they are more effectively used. In essence, S&OP is a structured approach to navigate a company toward its desired future state.

5 myths about S&OP – let’s debunk them

Now, let’s clear up some common myths and get to the bottom of the real value of S&OP.

Myth 1: S&OP is not a relevant operational process today

The concept of S&OP originated in the 1950s, evolving from a production-centric approach to enhance efficiency. It was never designed to be a process for gaining detailed knowledge of every aspect of a company’s operation. Instead of striving for operational precision, S&OP is a tool for planning and fostering flexibility. Today, the fundamental need for tactical planning persists.

Many of today’s companies find themselves caught in the “too late corner.” They primarily focus on assessing their order backlog for the next couple of months, and as a result, they struggle to maintain control and end up spending their time putting out fires.

To overcome this, it is not viable to merely focus on the short term and hope for the best. Looking further into the future and making the most of the information you can capture is essential. Companies must adopt a broader perspective and examine the dynamics of supply and demand across extended time horizons. This entails not only periodic assessments but also frequent monitoring to identify fluctuations and their recurring patterns. A key objective is to understand the flexibility required and how quickly you should adjust your capacity.

Myth 2: It is not worth it, as we cannot predict the future anyway

S&OP is not about predicting the future – it is about planning for the future. Sure, you can use it to analyze historical sales data and create forecasts to align supply with demand. But to unlock the true potential of S&OP, it should be used to understand where your business is today and where you want to be in the future. What is your current trajectory, and what is your desired destination?

This approach places you in control rather than at the mercy of the process. It allows you to gently steer your business in the intended direction. You can accelerate, decelerate, and manage marketing and capacity efforts accordingly.

Used correctly, S&OP is a multifaceted decision-making and gap-bridging process designed to guide your company toward its strategic objectives. It is not about predicting the future – it is about understanding the evolving reality that lies ahead.

Myth 3: S&OP is yet another time-consuming planning process

If this sounds familiar, it might be time to ask yourself this question: How much of your time do you spend on firefighting? The answer might reveal a significant gap in your organizational structure – an absence of a well-defined S&OP process.

As the old saying goes, “If you don’t plan, you plan to fail.” This is especially true when it comes to S&OP. While it isn’t a magic bullet that guarantees flawless outcomes, it serves as a cornerstone for informed decision-making and facilitates a culture of collaboration.

Imagine sending eleven soccer players onto the field without briefing them on their roles, the game strategy, or whether they should play defensively or offensively. Chaos would occur, and the chances of succeeding would be fairly small.

In the world of S&OP, the scenario is strikingly similar. Planning not only saves you from the chaos of reacting to problems as they arise. It also grants you a more transparent path toward achieving your objectives. S&OP, when executed right, is not just another planning procedure, but a value-adding mechanism.

Myth 4: S&OP is solely a supply chain issue

This myth is rooted in a silo mentality where each department operates in isolation, failing to communicate or collaborate effectively. This is often driven by performance metrics solely tied to individual functions. A “you handle yours, and I’ll handle mine” attitude dominates the workplace, and the overall success of the company – which should be the primary objective – becomes overshadowed.

In contrast, S&OP is the opposite of this approach. It shifts the individual focus towards an integrated plan and places the organization within an ecosystem where all departments work together towards a common goal, collectively contributing to the company’s success. The breakdown of traditional silos and adoption of a broader perspective fosters collaboration. Succeeding in S&OP is very much connected to acknowledging interdependence and prioritizing collective performance.

In summary, S&OP is not just a supply chain concern. It is a collaborative effort that involves the entire organization, including sales, operations, product development, finance, sourcing, procurement, and marketing.

Myth 5: A fancy S&OP tool is overkill when we have spreadsheets

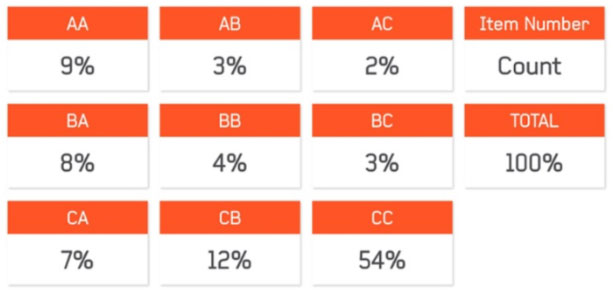

Even though technology has advanced, many companies still rely on spreadsheet programs such as Excel or rule-based processes in ERP systems to manage their S&OP. So, isn’t using spreadsheets good enough? Well, it depends on the purpose.

Excel is a great tool for creating prototypes to test ideas in the context of S&OP. However, it is primarily designed for data input and manipulation rather than supply chain planning. As it relies on manual data entry, it has significant limitations in supporting comprehensive planning requirements, making it prone to errors.

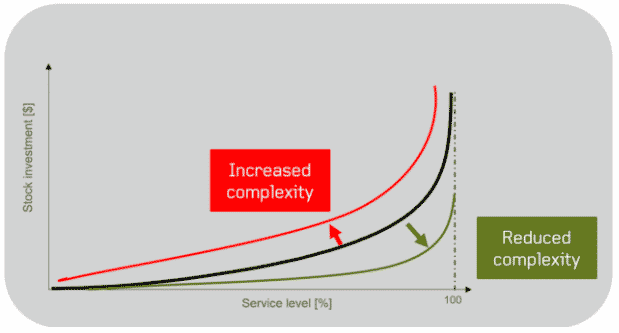

The problem usually arises as organizations grow in their product portfolio, markets, or volumes. The more data they put into the system, the more complex it gets. This often leads to shortcuts and inaccuracies, making it inefficient and difficult to manage. Consequently, businesses may experience higher costs and operational inefficiencies.

Relying on spreadsheets for supply chain optimization and critical business decisions simply isn’t sustainable. Companies need to realize that spreadsheets must be replaced with more robust solutions for S&OP that support their future business requirements.

Do you want to improve your S&OP process?

Don’t settle for outdated S&OP methods. It is time to say goodbye to manual and tedious Excel corrections and welcome a highly flexible and easy-to-use solution.

With a track record of over 1,000 successfully completed projects and a 30-year integration heritage, Optilon is a trusted supply chain optimization partner.

Our flexible system for S&OP can be tailored to align with your specific processes while remaining adaptable to your evolving business needs. It is easy to implement and offers effortless integration with other systems to streamline your operations seamlessly. Explore our S&OP offer here!